News

- 2024/04/06/

- 【2024年5月大正蔵ショップ・蒸留所見学のご案内】

- 2024/04/04/

- 【150万円寄付】令和6年能登半島地震 三郎丸蒸留所のスモーキーハイボール

- 2024/03/21/

- ※受付終了【講演のご案内・募集】4/5(金)開催 農業醸造家 八木 健太郎氏講演会

三郎丸蒸留所は、1952年の製造開始以来、

スモーキーな香りにこだわった

ウイスキーづくりを続けてきました。

一方で、この国のウイスキー文化を

より豊かなものへと変えていけるように

さまざまな挑戦も続けています。

守り続けてきた伝統に革新を重ねて、

富山の地ならではのウイスキーを

ウイスキーへの深い愛情とともに

日本全国へ、世界へ、発信していきます。

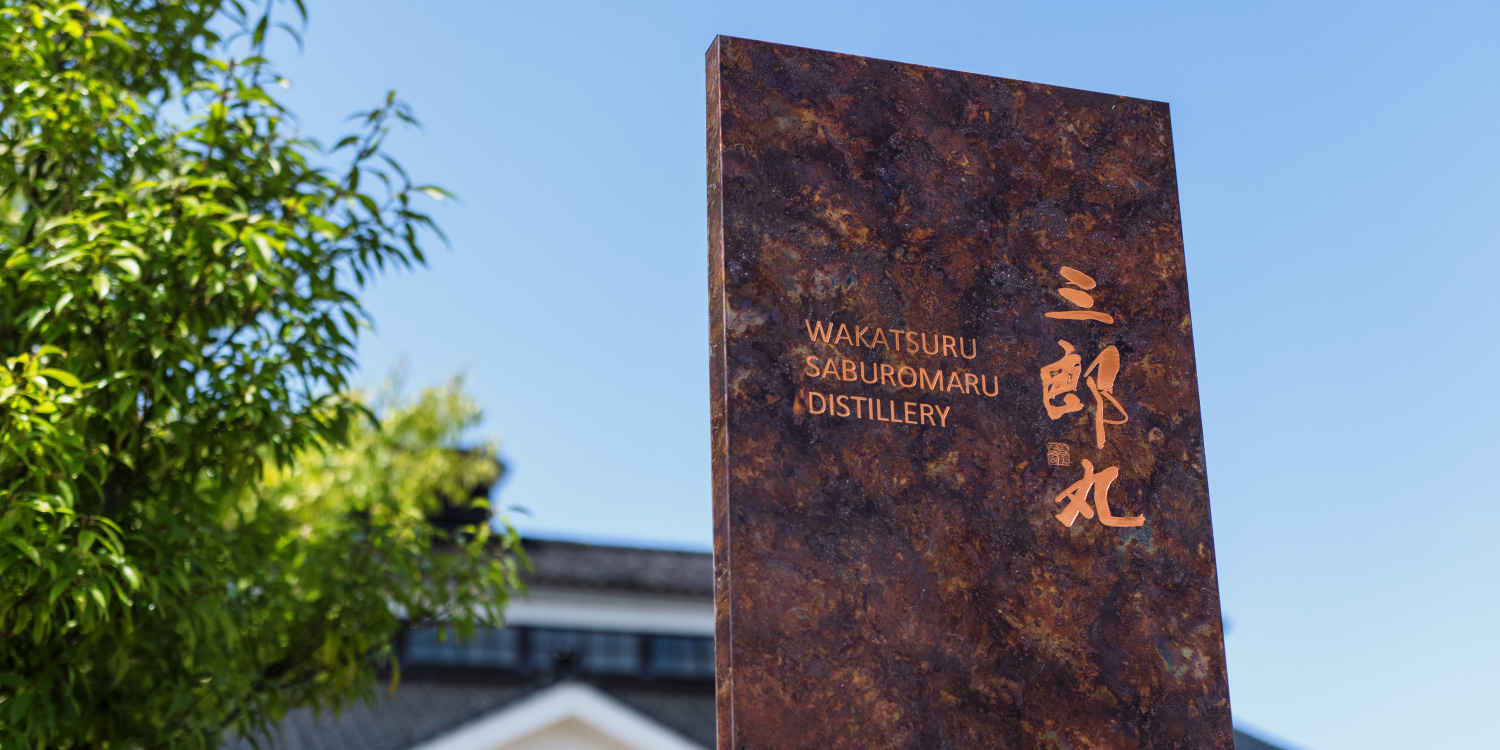

豊かな水と緑、そして文化を持つ富山県砺波市。

その三郎丸という地区で、三郎丸蒸留所の母体である

若鶴酒造が酒造業を始めたのは1862年のことです。

1952年よりウイスキーを製造してきたこの蒸留所は

2017年に「三郎丸蒸留所」として生まれ変わり、

富山の地からウイスキーの魅力を発信する

クラフト蒸留所として活動を続けています。

三郎丸蒸留所 マスターブレンダー&マネージャー

稲垣 貴彦

三郎丸蒸留所の母体である若鶴酒造が、ウイスキーをはじめとした蒸留酒の研究をスタートしたのは1947年のことです。1953年に発売された初の自社ウイスキー「サンシャインウイスキー」は、発売から70年以上を経て今なお地元富山を中心に多くの方に愛されています。しかしながら、国内ウイスキー需要の落ち込みとともに、当社のウイスキー事業もまた大幅な縮小を余儀なくされていました。

2016年、私は故郷の富山へと戻り、この三郎丸蒸留所の再生に取り組むことにしました。掲げたテーマは、「伝統と革新」。曽祖父が始めたウイスキーづくり、スモーキーなウイスキーへのこだわりを受け継いで「The Ultimate Peat(ピートを極める)」を掲げ、同時にジャパニーズウイスキーとして世界の舞台で勝負できる新たな価値づくりのために、さまざまなイノベーションに挑戦しています。

2016年秋、老朽化していた蒸留所を改修するためのクラウドファンディングを実施し、多くの方の支援を得て2017年に現在の三郎丸蒸留所をオープンしました。

2018年には最新鋭のマッシュタンを導入、2019年には富山県高岡市の伝統産業である高岡銅器の技術を活かして世界初の鋳造製蒸留器「ZEMON」を発明。梵鐘メーカー老子製作所と富山県工業技術センターでタッグを組み共同開発しました。

また同時期、同じく富山県の南砺市井波地区に受け継がれてきた木工の伝統技術を活用し、地元の島田木材・山﨑工務店との協働プロジェクトとして、富山県産ミズナラ材を用いた「三四郎樽」の生産もスタートしています。

さらに2021年には、「T&T TOYAMA」としてジャパニーズウイスキー専門のボトラーズ事業も開始しました。

どれも前例がない中でのチャレンジでしたが、共通しているのは「富山でしかつくれないウイスキー」をつくり、世界へ届けたいという思いです。

三郎丸蒸留所が「ここにしかないウイスキー」を追求することは、これまでほとんどが大手メーカーだった日本のウイスキー産業に多様性を生み出すことにつながります。

スコットランドには130か所以上の蒸留所があり、それがスコッチの裾野の広さ、奥深さを形成しています。私が富山に戻ってきた2016年には、日本のモルトウイスキー蒸留所は大手を含めてもわずか9か所。2022年現在では計画中のものも含めると70か所ほどと大幅に増えたものの、それでもスコットランドと比べると規模も数も少なく、産業として成熟していないのも否めません。

昨今のジャパニーズウイスキー人気を一過性のブームで終わらせるのではなく、日本のウイスキー産業やウイスキー文化が本場スコットランドのように豊かなものへと一歩一歩近づいていくために、三郎丸蒸留所も力を尽くしていきたいと考えています。その挑戦と成長を見守りながら、ウイスキーを楽しんでいただけたらと思います。